Our

Infrastructre

Our choice of machinery relates directly to the stages of production and the quality control process. We have a full-fledged Laboratory comprising all the analytical equipments required to determine the right quality & composition of raw materials. All furnace additions are duly analyzed and pre-treated here.

Special moulding techniques have been developed to improve upon the roll quality for chill as well as the other Rollers. The high quality scrap (with controlled sulphur & phosphorous and other raw material), once tested, move to the latest designed Induction Melting Furnace for clean and homogeneous melt of proper composition.

Proper temperature control during the course of the heat and at the time of pouring of the roll is exercised with the help of Immersion and Optical Pyrometers.

Rollers then move to our large Machine-Shop, where each roll first passes through a series of heavy Roll-Turning Lathes for Proof Machining. At this stage, various tests are carefully carried out to determine if the roll is zero-defect and qualifies for further processing. A series of Metallographic and Mechanical tests monitor the structural homogeneity and ensure that Rollers are free from cracks, blow holes, gas holes, etc. Hardness is measured using the 'Shore', 'Vickers' & 'Dynamic' Hardness Testers.

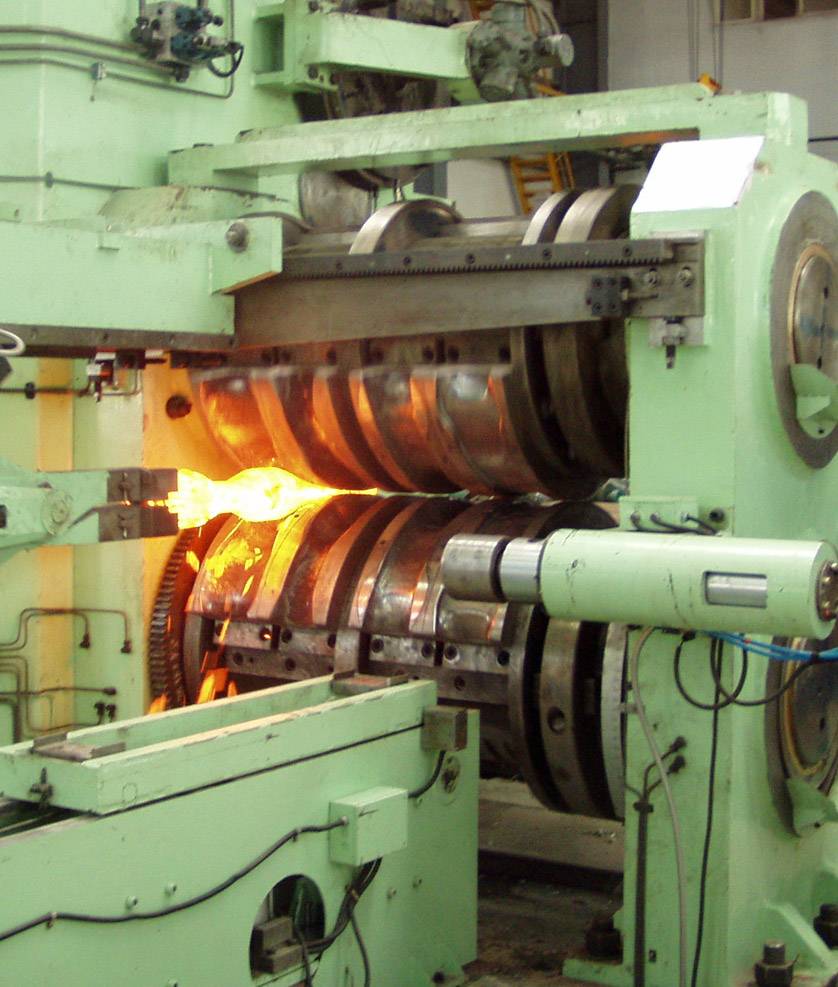

The Rollers meeting all the stringent tests to our complete satisfaction are then sent to the rest of the machine-shop, comprising High Precision Lathes, Radial Drill Machines, Boring Machines, Wobbler Milling & Grinding Machines, etc.

Hollow Rollers are dynamically balanced at different RPM to ensure their friction free movement. Finally the Rollers, as required, are tested by means of Non-Destructive testing methods like ultrasonic, magnetic particle inspection and dye-penetrant tests and the best possible quality of roll without surface and internal defects is ensured.

For large or critical Rollers, samples are removed from the Rollers to carry out Tensile, Impact and Microstructure tests to ensure optimum properties in service. Roll material and the groove design are major factors affecting rolling performance and roll life. It is after these series of tests and quality control process that we finally present our Rollers for the ultimate inspection, approval and delivery. Rollers are always dispatched with the identity number engraved on the wobbler face.